ABSTRACT-SCOPE

GREENUPGRADE

Valorization of green energy for enhancing the robustness and upgrading performance of anaerobic digestion systems– is a project aimed to address critical issues that bound biogas upgrading with biological processes fromtheir successful scale-up.

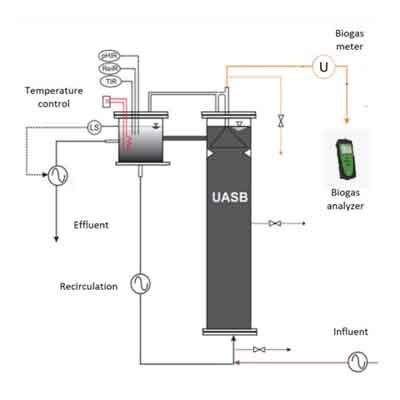

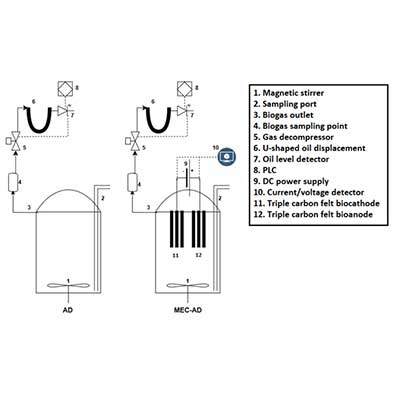

The targeted breakthrough of the this work is a combination of multiple actions that will boost alternative solutions towards their practical implementation. In order to achieve this goal, during GREENUPGRADE, different biological systems are constructed, operated and compared in terms of biogas upgrading and wastewater treatment. During GREENUPGRADE a trickle bed reactor (TBR) reactor is combined with an up-flow anaerobic sludge blanket (UASB) reactor and operate as an ex-situ biogas upgrading unit. The biogas is produced from the UASB reactor. Additionally, in-situ biogas upgrading is explored using an UASB reactor with hydrogen injection using microbubbles. Only recently scientists found that the integrated MEC-AD technology (electrofermentation) is a promising solution for simultaneous wastewater treatment and biogas upgrading.

This project explores the synergistic effect of hydrogen injection and applied potential in an MEC- AD reactor, on biogas production rate and quality. Additionally, a prototype MEC-AD bioreactor with multiple cathode electrodes is constructed and operates for higher exploitation of the AD bulk. All systems are assessed in terms of biogas production rate and quality and wastewater treatment under various operational parameters (gas feeding rate, gas diffusion system, different operation modes, gas flow rate,different types of real wastewaters, applied voltage, number of cathode electrodes for the MEC-AD units etc.)

Acknowledgements

GREENUPGRADE

The research project “GREENUPGRADE: Valorization of green energy for enhancing the robustness and upgrading the performance of anaerobic digestion systems” is implemented in the framework of H.F.R.Icall “Basic research Financing (Horizontal support of all Sciences)” under the National Recovery and ResiliencePlan “Greece 2.0” funded by the European Union – NextGenerationEU (H.F.R.I. Project Number: 15522).

CET 2025, 19th International Conference on Environmental Science and Technology, Kos, Greece

Fragkos, G. Kanellos, E. Kotsikas, E. Pournara, A. Tremouli, G. Lyberatos, A. Vlysidis. Α Microbial Electrolysis Cell-assisted Anaerobic Digestion process for enhanced treatment of industrial potato processing wastewater. CEST 2025, 19th International Conference on Environmental Science and Technology, Kos, Greece, 3-6 September 2025. [Accepted].

G. Kanellos, O. Fragkos, D. Flari, A. Tremouli, G.Lyberatos. The synergistic effect of H2 injections and applied potential on biogas production during the treatment of industrial potato processing wastewater in a Microbial Electrolysis Cell-assisted Anaerobic Digestion system. CEST 2025, 19th International Conference on Environmental Science and Technology, Kos, Greece, 3-6 September 2025. [Accepted].

Communication and dissemination activities

Work Packages

The work plan of GREENUPGRADE has been structured in 4 Work-Packages (WPs)

that cover a 24 (2 years) time period.

Particularly, during WP1 a UASB reactor and a TBR for ex situ biogas upgrading will beconstructed and operated under various conditions. The main aim of WP1 is to evaluate the TBR system as a biogas upgrading technology for the biogas produced from a UASB reactor by using hydrogen source from a hydrogen generator (electrolyzer). In parallel, during WP2, the enhancement of biogas production is tested by injecting hydrogen in a UASB bioreactor.

Furthermore, the main aim ofWP3 is the construction and operation of two novel MEC-AD bioreactors for biogas upgrading. WP4 focus on the dissemination and exploitation of all the valuable data produced from the project. The project’s final target is to propose the most promising biological methods (via hydrogenotrophicmethanogenesis or electrofermentation) for biogas upgrading, at the end of the project life

A) UASB reactor, B) gas-liquid separator, C) water bath for temperature control and D) recilculation line with pH and ORP electrodes